Brent Lea Recreation Ground, Hounslow

With the award of the tender, London Surfacing were tasked with creating a new footpath that would circle the park, totalling nearly 445 square metres.

Some of the existing grass surface was dug out to shape the new footpath.

Nearly 700 linear metres of new timber edgings were installed on either side of the footway.

The sub-base was compacted & a geotextile membrane was laid to supress vegetation.

Roughly 200t of type 1 was laid and compacted to provide a firm base for the top surface.

The footpath was finished off with a 50mm layer of Breedon Gravel, in a golden amber colour.

The ground now has a safe and natural looking pathway to enable visitors to enjoy the park all-year round.

Halley House, Arcola Street

We completed an unusual project on the third floor balcony of a school in Hackney.

London Surfacing were approached by our clients City Axis with a view to undertaking work at Halley House School in Hackney.

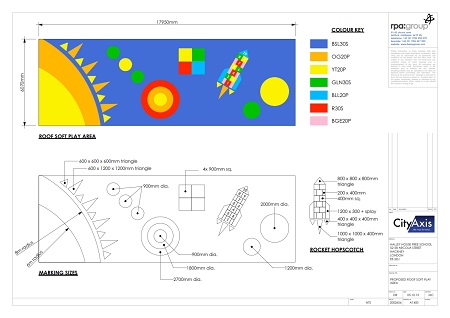

The school hired an architect to produce a plan of the proposed rubber safety surface they wanted installed on an outside balcony.

The design mainly consisted of a blue base with a number of multi-coloured shapes built within the base colour.

The logistics of getting the material up to the third floor was co-ordinated between LSC & the School. The Safetyfall was to be laid at a thickness of 40mm.

The result: A very happy client and school

The children now had a play area balcony that was safe but also bold and very colourful.

The finished product even seems to improve upon the look

on the architects drawing.

Private resident driveways, Barnet & Finchley

Barnet

An extensive facelift on a private residence driveway, looking to change a worn looking shingle drive to a more modern, clean looking finish.

After excavating and removing the shingle and a sub-base of soil, we installed edgings, adjusted manhole levels and carried out brickwork repairs to the original wall.

Extra brickwork was laid to create new borders & a dwarf wall. Fully automated, retractable bollards were installed and the drive was laid with a 90mm thickness of binder course.

Then the process of laying the gold resin-bound layer began.

The end result was a totally transformed driveway, that looked modern, clean, colourful and is very practicable to clean.

Finchley

Another stunning transformation from a tired tarmac laid drive to a clean-looking, vibrant resin-bound in slate grey.

Breaking out the old surface, adding a new layer of type 1 stone, then a compacted porous binder course and finally the resin-bound.